Nutritional supplement manufacturers can also benefit from ERP

All types of businesses rely on enterprise resource planning software, especially companies in manufacturing industries. Natural Products Insider...

1 min read

Single Source Systems, Inc. : Updated on February 23, 2023

Please enjoy this guest blog from Single Source's partner CADTalk!

Not all manufacturing companies need integration. Many manufacturers release a few new product designs per month or year. Entering bills of material (BOMs) into the system is not time-consuming and doesn’t require a lot of resources.

Engineer-to-order. These manufacturers create hundreds of new designs and items each month. Each time they create a new model, they must enter that BOM into the ERP. These organizations must consider connecting the ERP and CAD together because they:

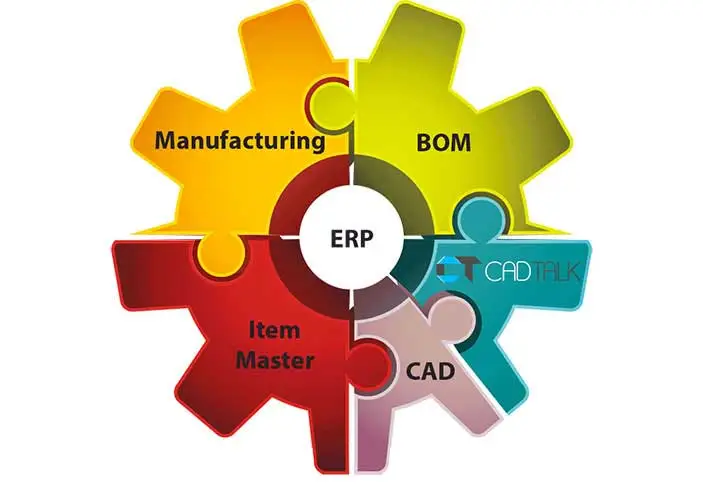

On the surface, direct linking the design and manufacturing bill of material appears to be a simple decision. However, this concept causes limitations. The CAD BOM consists of a list of assemblies, components, and geometry. The ERP BOM has additional data related to routing steps, runtimes, product codes, and a host of other manufacturing-related data. Linking demands that CAD contains all the information that the ERP requires even if it is unnecessary and irrelevant to the CAD design. If these data don’t exist in the models, then the engineers must change their process to prepare the models before the company can benefit.

CAD-ERP integration is CRITICAL for engineering to order companies. To get immediate improvement without a process change, CADTalk harnesses the CAD data and smoothly integrates your data into your ERP to unleash the full functionality of its suite of tools. This technology directly translates into business success for both manufacturing and distribution companies. Manufacturers can better plan, manage and control production while distributors can manage supply chain financials, optimize inventory and improve profitability.

When CAD and ERP are talking, the depth of integration is limitless. Data resides in the software where it belongs, and design engineers and operations management owns their parts and unnecessary duplication is avoided. Allowing the CAD and ERP to communicate with one another supports a flexible and dynamic integration. Why limit oneself to the ridged, inflexible binding that a link creates when TALKING IS THE BEST method for solving challenging problems?

Schedule a one-on-one consultation with one of CADTalk's CAD-ERP integrations specialists to discuss your current processes.

All types of businesses rely on enterprise resource planning software, especially companies in manufacturing industries. Natural Products Insider...

On-site IT systems may no longer be the de facto option for firms that need to be agile. Manufacturers considering cloud computing as their next...

Resolute Industrial, formerly part of Johnson Controls, is a major provider of water and air cooled chiller rental services, compressor...